Subcategories

-

Soils Drying Ovens

SDO Soils Drying Ovens

225 litre Soil Drying Oven

425 litre Soil Drying OvenSDO225/TDIGThe Genlab range of Soil Drying Ovens offers a selection of highly efficient, reliable and cost effective units to suit most material testing requirements. These range of ovens are designed for drying large quantities of soils and aggregate samples and maintains temperature in accordance with BS EN and ASTM requirements. They feature our latest touch screen control system, which offers intuitive control and excellent accuracies designed for soil drying ovens.The SDO225 and 425 model are also available with a 3 digit PID controller for lower cost options.

Specifications

- 4 sizes 225 to 1000 litres

- Temperature range:

40ºC to 180ºC (225 and 425 models)

60ºC to 200ºC (750 and 100 models) - Digital Control System

- Fan assisted circulation

- Excellent Stability (<1ºC)

- Low temperature uniformity

Options

- Access ports (25, 50, 75 or 100mm)

-

Traceable calibrations to national standards

-

Extended warranty

- Reinforced shelves (upto 40Kg)

- Integral Data Logger with reporting firmware (TDIG Only)

SDO Design

The exterior is constructed from sheet steel finished in an easy clean powder coated paint. The interior chamber is made from mild steel coated with aluminium (CLAD).

Fitted with fixed shelf runners and removable chrome plated wire grid shelves.SDO Heating

Heated by Incoloy sheathed elements positioned in the either the base or side of the unit. Fresh air is entered into the oven and passed across the heating element and into the chamber. Air is then continuously circulated around the chamber with around 15% expelled through the top vent which is replaced with the incoming air.

SDO Controls

The control system comprises of a bespoke touch screen user interface that offers both accurate temperature control and an integral overheat system by using 2 individual PT100 sensors. Advanced features can be turned on and off to suit bespoke heating applications and tailored to customer preference. Oven trending is displayed for up to 48 hours and optional upgrades are available for alarm outputs.

Specifications

Genlab ref.

NumberCapacity

(litres)Internal DimensionsH x W x D cmExternalH x W x D cmNo. of

Shelves ..positionsKW /VoltsWeight

(kg)SDO/225/DIG 21054 x 92 x 4294 x 106 x 57 3..42 / 23096SDO/425/DIG 44576 x 92 x 6497 x 141 x 81 4..53 / 230130SDO/225/TDIG 21054 x 92 x 4294 x 106 x 57 3..42 / 23096SDO/425/TDIG 44576 x 92 x 6497 x 141 x 81 4..53 / 230130SDO/750/TDIG 750106 x 92 x 77142 x 157 x 95 5..86 / 415320SDO/1000/TDIG 1005142 x 92 x 77178 x 157 x 95 5..116 / 415360Ordering

All units have CLAD interior with digital controller and overheat thermostat as standard.

Where options are required simply add the option code to the original reference.

E.g. SDO/225/DIG with access port becomes SDO/225/DIG/AP.

Contact sales for bespoke options.Option codes

3 Stage Timer /TIM

Integral DataLogger /ITL

Access ports /AP

Traceable calibration /SPC

3 Point traceable calibration /3PC

Extended warranty /X1

Reinforced shelves /RS

Integral Data Logger /ITL -

Thin Film Ovens / Loss...

Loss on Heat / Thin Film Ovens

This dual purpose oven is designed to perform Loss On Heat and Thin Film Test for bitumin and asphaltic materials and complies to the requirements of BS2000 ASTMD6, D1754 & AASHTO T47, T179

Specifications

- Temp range 40ºC to 200ºC, preset at 163ºC

- Supplied with 2 off aluminium turntables

- Stainless steel interior

- Independent overheat thermostat

- High accuracy

- Excellent stability

- Low chamber uniformity

Options

- Audible warnings

- Traceable calibrations to national standards

- Bespoke stands and stacking kits

- Extended warranty

- Bespoke solutions available upon request

Design

The exterior is constructed from sheet steel finished in an easy clean powder coated paint. The interior chamber is made from 304 stainless steel. The unit is well insulated and has a double glazed window to view the test chamber.

Two rotating turntables of 13.5in diameter are supplied to perform both tests

Heating

Heated by Incoloy sheathed elements positioned in the base of the oven offering natural convection.

Controls

The control system comprises of a highly accurate PID temperature controller and an independent overheat thermostat with calibrated scale and tamper proof lock. Temperature is controlled and pre-set at 163ºC

Specifications

Genlab ref.

NumberCapacity

(litres)Internal DimensionsH x W x D cmExternalH x W x D cmWattageVoltageWeight

(kg)LOH/TFO 9038 x 52 x 4669 x 87 x 63 100024070LOH/TFO1 9038 x 52 x 4669 x 87 x 63 100011072Ordering

All units have stainless steel interior with 2 turntables.

Where options are required simply add the option code to the original reference.

E.g. LOH/TFO with audible warning and traceable calibration becomes LOH/TFO/AWA/SPC.

Contact sales for bespoke options.Option codes

Audible Warning - AWA

Single Point Calibrations - SPC

Stand - STAND

Extended Warranty - X1 -

Rolling Thin-Film Ovens

Rolling Thin-Film Ovens

The Rolling Thin-Film Oven (RTFO) procedure provides simulated short term aged asphalt binder for physical property testing. Asphalt binder is exposed to elevated temperatures to simulate manufacturing and placement aging. The RTFO also provides a quantitative measure of the volatiles lost during the aging process.

The exterior is constructed from sheet steel finished in an easy clean powder coated paint and the interior chamber is made from stainless steel.

The control system comprises of a microprocessor digital controller and overheat thermostat with calibrated scale and tamper proof lock.The standard Rolling Thin-Film Oven test is:

AASHTO T 240 and ASTM D2872.

The Rolling Thin-Film OvenOven Specification

- Complies to the requirements of ASTM D2872

- Internal dimensions (mm): 380 high x 480 wide x 440 deep

- External dimensions (mm): 800 high x 710 wide x 660 deep (add 40mm to depth for door handle)

- Double wall construction with high density thermal insulation

- Non rusting grade 304 Stainless steel interior

- Easy clean powder painted steel exterior in light grey (RAL 7035) textured finish

- Top mounted fan constructed with an air plenum as described in the ASTM D2872 specification and is fitted with a squirrel-type fan blade for better uniformity of air and temperature distribution

- Equipped with air jet for blowing heating air into each bottle at its lowest point of travel

- Base mounted elements

- Vented to atmosphere

- Single front opening, side hinged door with positive quarter turn latching mechanism

- Double glazed window in door for viewing the test chamber

- Top mounted controls comprise

- Dual display microprocessor digital control

- Independent overheat thermostat

- Mains switch

- Flow meter to control airflow

- Indicator lamps

- 1500 watts

- Supplied with a built-in 305mm diameter vertical circulator carriage to hold 8 glass sample containers rotating at 15 rpm ±0.2rpm (glass containers not supplied)

- Temperature is controlled and pre-set at 163°C ± 1°C

Ordering codes

RTFO – Rolling thin film oven – 220-240 volts

RTFO1 – Rolling thin film oven – 110-120 volts -

Materials Testing Ovens

Genlab Material Testing Ovens

The Genlab range of Material Testing Ovens offers a selection of highly efficient, reliable and cost effective units to suit most material testing requirements. It is an ideal general purpose oven. This range is available with ‘simple to use’ thermostatic operation, or, with Genlab’s latest touch screen control system which offers intuitive control. Both control systems offer excellent accuracies designed for material testing applications.

Specifications

- 4 sizes 50 to 200 litres

- Temperature range: 40ºC to 250ºC

- Excellent stability (<1ºC)

- Low temperature uniformity

- Fan assisted circulation

- Themostat Features

Easy to use thermostatic control

Independent overheat thermostat - Touch screen feature

3.2in touch screen PID interface control

On screen historical trending (48 hours)

Manual overheat reset

Options

- 8 stage profile control (TDIG only)

- Count down timer (TDIG only)

- 24/7 real time clock operation(TDIG only)

- Access ports (25, 50, 75 or 100mm)

-

Traceable calibrations to national standards

-

Extended warranty

- Reinforced shelves (upto 40Kg)

MTO Design

The exterior is constructed from sheet steel finished in an easy clean powder coated paint. The interior chamber is made from mild steel coated with aluminium (CLAD).

Fitted with fixed shelf runners and removable chrome plated wire grid shelves.MTO Heating

Heated by Incoloy sheathed elements positioned in the rear of the unit. Air is entered into the rear of the unit, passed across the heating element and into the chamber.

MTO Controls

Available with 2 options, thermostatic or touch screen digital interface. Thermostatic control comprises of a direct reading thermostat and overheat thermostat, both with calibrated scales and tamper proof locks. They also include a mains switch with heating and overheat lamp indicators.

Touch screen option offers both accurate temperature control and an integral overheat system by using 2 individual PT100 sensors. Oven trending is displayed for up to 48 hours and oven status is shown on the 3.2 in colour screen. Advanced timer options are available in this model.Specifications

Genlab ref.

NumberCapacity

(litres)Internal DimensionsH x W x D cmExternalH x W x D cmNo. of

Shelves ..positionsElementRating(W)Weight

(kg)MTO/50/F/TDIG 4733 x 49 x 2960 x 61 x 64 2..31000 45MTO/100/F/TDIG 9045 x 49 x 4172 x 61 x 77 3..4125060MTO/150/F/TDIG 13255 x 49 x 4982 x 61 x 85 3..5175070MTO/200/F/TDIG 18075 x 49 x 49102 x 61 x 85 4..7225080MTO/50/F 4733 x 49 x 2959 x 61 x 64 2..31000 45MTO/100/F 9045 x 49 x 4171 x 61 x 77 3..4125060MTO/150/F 132 55 x 49 x 49 81 x 61 x 85 3..5 1750 70 MTO/200/F 180 75 x 49 x 49 101 x 61 x 85 4..7 2250 80 Ordering

All units have CLAD interior with either thermostat or touch screen interface as standard.

Where options are required simply add the option code to the original reference.

E.g. MTO/100/F/TDIG with timer and access ports becomes MTO/100/F/TDIG/TIM/AP

Contact sales for bespoke options.Option codes

3 Stage advanced Timer / TIM (TDIG models only)

Access ports / AP

Traceable calibration / SPC

Extended warranty / X1

Stands/Stacking Kits / STACK -

Riffle Boxes

Riffle Boxes

These sample dividers are constructed of heavy gauge sheet metal finished in an easy clean powder coated paint and are supplied in a range to meet the requirements of BS 1377, 1924 , 812 and ASTM C136.

Each riffle is supplied complete with divider and three containers.

Specifications

Genlab ref. Number Slot width

(mm)No. of

slotsGenlab ref. Number Slot width

(mm)No. of

slotsRB607 712RB630 3010RB610 1012RB638 388RB613 1312RB640 408RB615 1512RB645 458RB620 2010RB650 508RB625 2510RB665 658 -

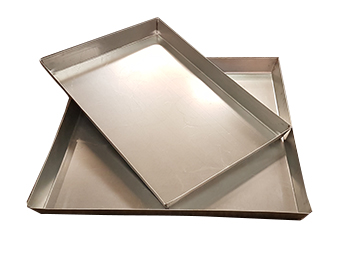

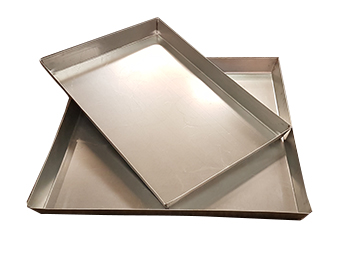

Trays

Trays

A range of heavy duty galvanised steel nesting trays and quartering trays (one side removed).

Nesting Trays

Genlab ref. Number Dimensions (mm)Weight (kg)Genlab ref. Number Dimensions

(mm)Weight (kg)T501 254 x 254 x 381.00T507 760 x 760 x 637.00T502 306 x 306 x 381.40T508 910 x 610 x 767.50T503 460 x 460 x 502.75T509 910 x 910 x 769.50T504 610 x 305 x 504.40T510 1040 x 1040 x 7612.0T505 610 x 610 x 636.00T511 1200 x 1160 x 5015.0T506 760 x 460 x 636.00T512 406 x 406 x 502.25Quartering Trays

Genlab ref.

NumberDimensions

(mm)Weight (kg)T601 910 x 910 x 768.0TH602 (with handles) 1040 x 1040 x 7612.0 -

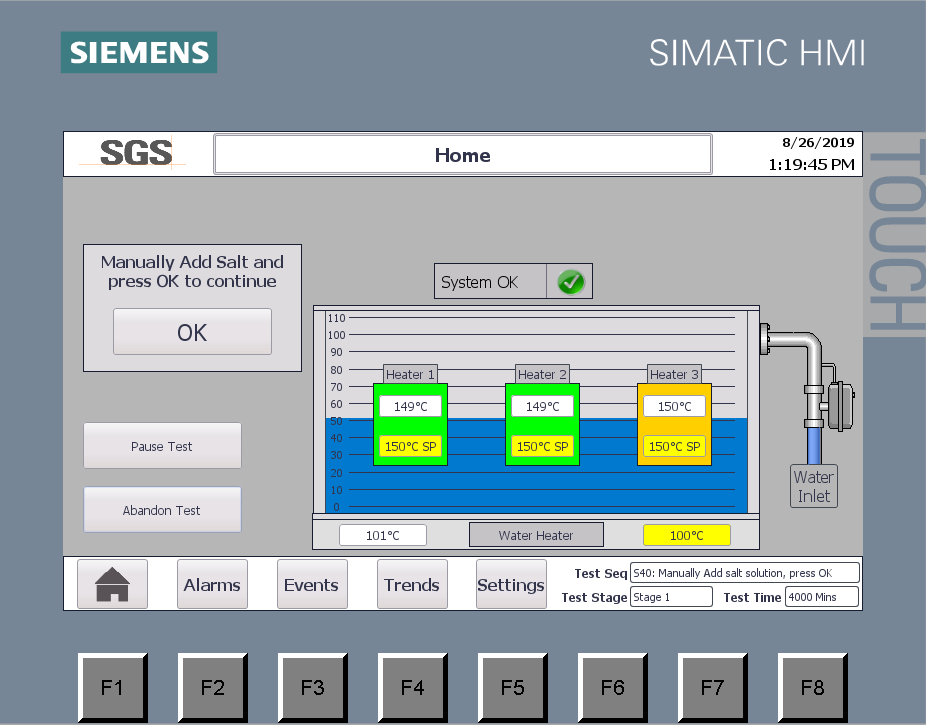

CUI Test Equipment

Genlab CUI Tester

Using Genlab’s 60+ years of thermal engineering experience, we offer custom built test equipment to suit specific ISO standards. Our latest CUI tester is a custom built product that simulate conditions to meet the ISO 19277 qualification testing required for many Petroleum, Petrochemical and Natural Gas industries. Working closely with UK leading testing houses, we discuss ISO specifications and offer a unique ‘Concept, to Product Design and Build’ service using the latest PLC control systems.

Specifications

- Energy efficient, <5KW max for testing 3 samples

- Integral Overheat shut down system

- 415V 3 Phase + N

- Stainless steel interior and exterior

- Extraction hood designed to vent chamber salt water (75mm)

- Automated fill control, calibratable to local conditions

- Compact solution (120cm H x 90cm W x 80cm D)

Features

- Automated Test Sequences, simply press ‘GO’ then data capture in 1008 hours

- PLC Control

- 3 Sample Testing

- Auto level fill control

-

Dry boil detection

-

4 Zone temperature control and pre test calibration sequence

- Historical Trending

- Easy to use intuitive touch screen control

- Alarm and event history

Ovens and associated sampling equipment for Material Testing

SDO Soils Drying Ovens

This range of ovens is designed for drying large quantities of soils and aggregate samples and maintains temperature in accordance with BS EN and ASTM requirements.

MTO Materials Testing Ovens

The Genlab range of Material Testing Ovens offers a selection of highly efficient, reliable and cost effective units to suit most material testing requirements and is an ideal general purpose oven. Featuring our latest touch screen interface.

Loss on Heat / Thin Film Ovens

This dual purpose oven is designed to perform the loss on heat test and thin film test for bitumen and asphaltic materials.

Rolling Thin-Film Ovens

Genlab offer a range of Curing Ovens that are ideally suited for the curing of composite materials.

Classic Water Baths

The GENLAB range of unstirred water baths is ideal for general laboratory use and are economical, reliable and very cost effective.

Prime Digital Water Baths

The Prime WBH are the flagship brand of GENLAB water baths. They are built to the highest standards with integral timers and profile modes.

CUI Coating Test Equipment

Genlab offer design and build of bespoke test solutions to meet various ISO standards. This CUI tester was designed around the latest ISO19277 specification..

Bench Top PID Control Stations

Genlab have designed a user friendly PID contol station with integral temperature safety system

Riffle Boxes

These sample dividers are constructed of heavy gauge sheet metal finished in an easy clean powder coated paint and are supplied in a range to meet the requirements of BS 1377, 1924 , 812 and ASTM C136.

Trays

A range of heavy duty galvanised steel nesting trays and quartering trays (one side removed).

Genlab manufacture a comprehensive range of drying and testing ovens specialist asphalt testing ovens. The units meet the requirements of both BS and ASTM requirements. To complement our oven range we also manufacture a wide range of riffle boxes and trays. Genlab achieved ISO9001 accreditation in 1994 and all of the units are CE marked.

We are able to offer a full custom build service to meet customer’s special requirements.

All Genlab products are manufactured in the United Kingdom and we are the UK's leading supplier of soils and asphalt testing ovens.

Search

Need Some Advice?

Contact us

* REQUIRED FIELDS

All Genlab products come with a two year warranty

Bespoke Ovens Gallery

Click here to view some of the bespoke ovens we have built