Electronic design and manufacture of bespoke PCB's for OEM's

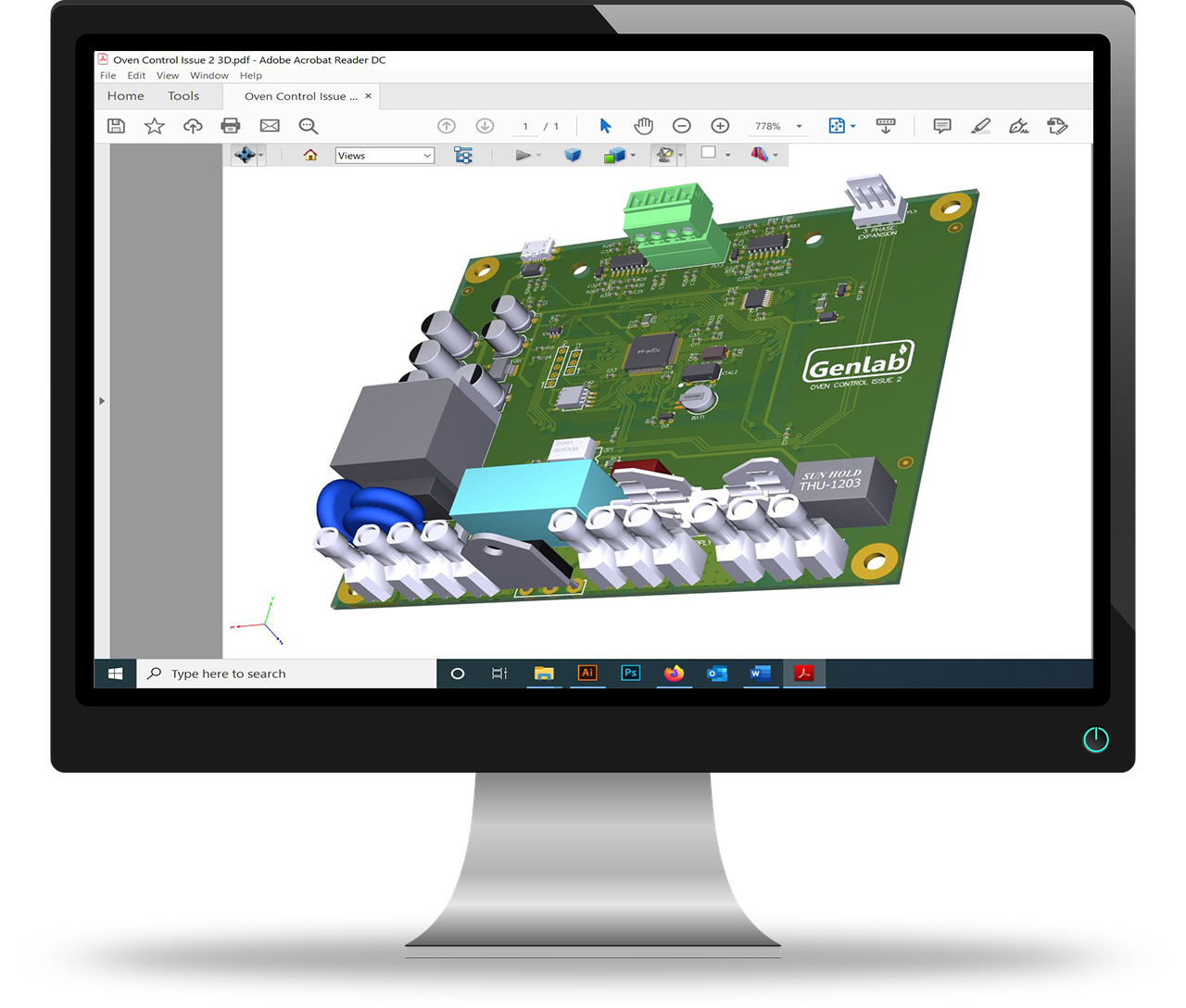

CAD Design

PCB build and test

Genlab have a wealth of experience in both thermal engineering and all designs of electrical control, interface and multi loop systems. We have successfully taken a variety of projects from initial concept stage, through design and development, into completed successful products. We pride ourselves in the close relationship we have with our clients, understanding their requirements and working together to create the optimum solution. Our customers are experts in their own markets, so combining this knowledge with our experienced design and manufacturing skills creates market leading products.

We have a dedicated team of electrical design engineers, PCB designers, mechanical engineers and a complimentary team of software engineers offering multi-skill platforms in multiple disciplines. We can offer full turnkey solutions and our partnering manufacturing facility is capable of single prototype batches through to 100,000 batch runs.

If you have a product idea, get in touch and we would be happy to discuss potential designs and solutions. Genlab specialise in PID loops, with logic handling and data recording, with expertise in air flow, pressure, humidity and level control. Whatever protocols your product needs to communicate with the outside world will be included in the PCB design. Our engineers have a wealth of experience with most of them including USB, RS232, RS485, Bluetooth, LCD, LED, Touch Screens, BACnet, Ethernet and Android. Our development team will be able to advise on the best protocol and seamlessly integrate it into your product design.

Features

- Turn Key Solutions

- Keep your own Intellectual Property rights to your concept

- Multi discipline teams : Hardware, software, mechanical and graphical designers

- Analogue or Digital hardware design

- Multi Layer PCB design

- EMC Compliance Testing

- Single batch prototype to 100K production runs

Options

- Multi loop PID systems

- Self tuning algorithms

- Choice of communications, RS485, ethernet, BACnet

- Integral datalogging

- Complimentary PC based firmware

- Precision mechanical fabrication and product interface

- Keypad Facia Design and Manufacture

Design through to concept

We make integrating electronics into your product easy. From concept through PCB layout design and prototyping to full manufacture and test. Discuss your product concept with our team in confidence, and under NDA if required, to explore its feasibility. We will then produce a development proposal outlining the concept of operation, agreeable project milestones with all associated costs and time scales.

Customers wishing to explore the viability of a potential product can take advantage of our ability to quickly and cost effectively explore a basic concept complete with prototype PCB design. This will enable us to provide an estimated product cost should the development go ahead.

First, your product will require a full schematic PCB design, including a number of different features:

The power supply may be AC mains or DC low voltage. The product may be low cost or high performance. We have already designed hundreds of different types of power supply and have the PCB layout design for whatever is required, which takes into consideration all environmental, legislative, power and budget requirements.

Product functionally may be controlled by simple logic gates or a Microprocessor, it may even require an integrated processor in an FPGA. Our engineers have many years experience of digital design using microprocessors from all leading manufacturers including ARM, Atmel, Cypress, Microchip and NXP. We also specialise in FPGA / CPLD development using VHDL with Altera and Xilinx. Whatever is the right product to do the job, we will incorporate it into our PCB design layout.

Even working with minimal specifications such as PCB dimensions and what inputs and outputs you require, we can produce full schematics and PCB layouts for you. Once the schematic design is complete using industry standard EDA tools, it moves seamlessly into the integrated PCB layout design software. Your products physical restrictions and interconnections along with manufacturability are all taken into account by the PCB designer during this design phase.

Now we are ready to produce a prototype or pre- production batch of your product. These assembled boards are used to validate the hardware design and to start developing the necessary firmware.

You may also require a PC or Android application to communicate with your product and display information. Our software development team will produce your software using C#, C++ or JAVA depending on the platform

Electronic Manufacturing Services

Unlike some other electronics companies, we provide a full range of electronics manufacturing services from rapid prototyping, obsolescence engineering support, product re-engineering, capability upgrades, design re-work, failure analysis or batch manufacturing. We pride ourselves on being one of the most competitive electronic manufacturing companies for electronic manufacturing services in the UK.

Genlab have the tools, knowledge and expertise to produce your products, to your specifications, to the highest quality and on time. We will gladly accept free issue components for your project, or if required, work with our approved supply chain to compile BOMs ready, offering our customers the best solution that works for them.

We use the latest in fully automated surface mount assembly equipment, facilitating fast accurate placement of components down to 1005 and uBGA, coupled with intelligent feeders for rapid setup and flexibility, allowing us to complete relatively small batches economically.

The additional advantage of this technology is the ability to react quickly to our customers requirements on short lead-time deliveries. This technology coupled with a team of experienced assembly technicians carrying out through hole conventional assembly enable Genlab to deal with whatever challenges are thrown our way.

Our highly trained staff can build complex surface mount technology PCB's by hand to provide a low cost solution for prototyping and small-scale production runs. Once your product is proven, or your production quantities increase, we can move seamlessly to our automated pick and place machine to reduce build time and costs.

Our electronics manufacturing services range from the supply of assembled boards using your free-issue components through to full sourcing and supply of parts, coupled with board build, final product assembly and wiring including all programming and functional test.

Over the years, we have built an established network of component suppliers from reputable electronics companies and can leverage our purchasing power to reduce the material cost of your products. We also work closely with a number of printed circuit board manufacturers, enabling us to source from the best possible supplier to meet your products complexity or quality standards.

Our test department is staffed by conscientious people, who take pride in ensuring your products leave us at the highest standard possible.

Whether it is purely visual inspection or full programming and functional test specified, they have a range of tools and equipment available to provide you with a trouble free product.

Everything from receipt of order to supply of finished goods is recorded on our computer systems providing us with full traceability of parts, assembly operations and test results. This process helps us to identify any possible weaknesses in products or parts and enables us to recommend any enhancements we may see in your product.

We create all manufacturing documentation necessary to provide us with the means to provide you with a quality product time after time all backed by a twelve month guarantee on everything produced. At the end of the development we pass over full Intellectual Property rights to you. However, this is often not the end of the development. Product upgrades and on going continued support are all part of the solution we offer in our partnership. We share the philosophy that the better your product is, the more products sales we all benefit from so ongoing support is key.

Our Bespoke Control Solutions division is also complimented with mechanical design, precision laser cutting, and graphical design services for overlay facias, and, a wealth of experience in supporting EMC testing.

Search

Need Some Advice?

Contact us

* REQUIRED FIELDS

All Genlab products come with a two year warranty

Bespoke Ovens Gallery

Click here to view some of the bespoke ovens we have built